GS Journal

British Made Sparkly Socks. Step into the factory

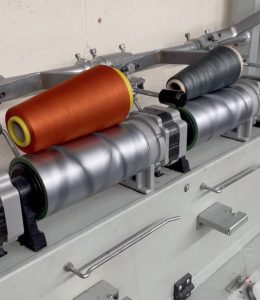

Whenever I visit my sock manufacturers, it’s like a sparkly colourful rainbow has hit the factory floor.

A flurry of sparkle and colour fills the machines, from twisting yarns, knitting, washing and seaming.

The artisans love this time of the season, with all the different manufacturing processes filled with sparkle and colour.

Earlier this year, I visited my factory to design and knit new styles and colourways with leftover yarn from last season,

ensuring there was zero waste in our production. Designing socks to be knitted with an intarsia machine allows the smallest cone of yarn to be knitted, so nothing goes to waste.

This is part of the process I love, getting creative and technical with small amounts of yarn to make sure that the knitting is efficient to run the knitting machines running during quieter periods whilst making very exclusive colours ways that will not be repeated.

Many of these sparkly yarns have FSC and Eco VERO certifications. Meaning that the wood which makes the viscose only comes from forests managed in an environmentally friendly way and that eco-friendly production processes have taken place.

All yarns have OEKO-TEX certification meaning that the textile fibres have been extensively tested and declared free of harmful substances. As a result, they are deemed completely safe for human health.

Some of the machines that knit my socks are very rare and traditional, including an intarsia machine which allows you to create patterns without loops on the inside; the Serora spiral stripe and Sigi zig zag stripe are great illustrations of how you can create a seamless pattern and colour block with this machine with a modern edge.

Shop the Collection here

Recent Posts

GS Collections

GS Sock Subscription

Subscribe and each month you'll receive a surprise pair of socks showcasing Genevieve's signature blend of premium yarns and contemporary patterns in seasonal, statement colours.