GS Journal

The Art of British Manufacturing | The Humble Button

Buttons are one of those small yet integral details which can make or break a garment, yet I imagine most people have never wondered how they are made or which materials they are made from, let alone the provenance of the buttons on their clothes. Let’s face it – with all the haberdashery shops disappearing from our high streets, it’s becoming much harder to simply buy a pack of buttons, so why would we spend time considering how they are made?

I have been known as a Button Hoarder since university, although I prefer to think of myself as a Collector. This was much to the horror of a former housemate who had a phobia of buttons! I wondered why she never came into my room for a chat, before I realised that the barrier was the huge glass container of buttons that sat outside my bedroom door! I would find interesting and unusual buttons at vintage markets, in charity shops and later on my travels to factories in Europe and the Far East. I placed them in the jar to save to sew onto garments to give them a unique edge, but I don’t think I really considered the materials of what they were made from at the time.

A few years ago, I received a call from Courtney & Co. inviting me to meet them for a cup of coffee to discuss their button making journey. Little did I know that our conversation would blow me away and that I would be telling friends, family, clients and anyone who would listen about the British Button Story for years to come. Believe it or not, a button is not simply just a button. Each button crafted by Courtney & Co. is helping to revive a craft which would otherwise have been lost.

Where are our buttons made?

All of the buttons used on Genevieve Sweeney cardigans are crafted in the UK by Courtney & Co. They are the last button makers in the UK, crafting a wide variety of beautiful buttons using traditional techniques and sustainable materials. You can read more about how they make their buttons on our Q&A here.

What materials are GS buttons made from?

I use buttons made from two different materials for my cardigans: Codelite® and Corozo.

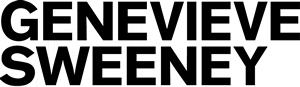

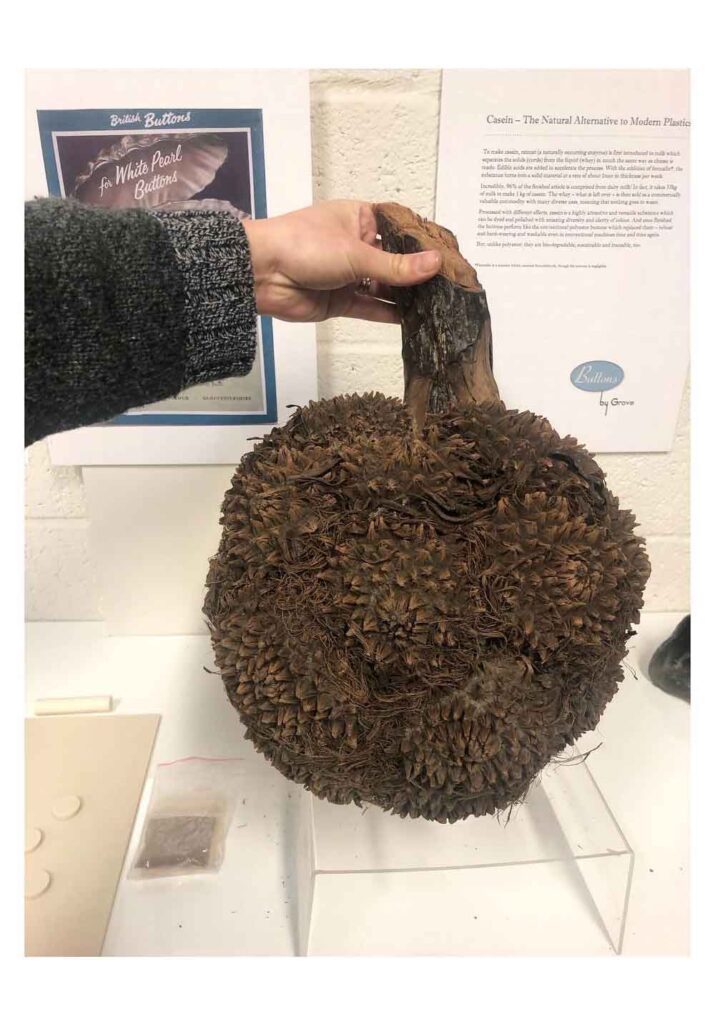

The buttons on the Aven and Alva cardigans are made from Corozo. This is a natural, sustainable and biodegradable material sourced from the nuts of Tagua palm trees which grow in Ecuador. Each mocochas (the fruit of the palm) holds up to 120 nuts, which will make around 500 buttons. The nuts are not harvested from the trees, rather the collectors wait until they have fallen off naturally to have less of an environmental impact. Wearing a garment containing Corozo buttons indirectly helps to maintain and protect ancient rainforests in Central America! In the image below, you can see the Corozo blanks before the buttons are turned and dyed, then the final buttons, custom-dyed to complement our cardigans.

The other material used for my cardigans is Codelite®. This is another natural, sustainable and biodegradable material which is made from conventional dairy milk, derived from 96% milk casein which is hardened in layers of 1mm per week. This creates a solid material which the buttons are then cut out of and turned. They have a wonderful pearl-like aesthetic that takes colour beautifully. We choose custom colours for our Codelite® buttons to complement each colour of our cardigans.

Below, you can see the dyeing process of these buttons, with a custom deep autumnal burgundy colour for our Alva lambswool cardigan and a bright blue that picks out the accents of blue in the pink Alva cardigan.

Fun facts about our buttons

- All of our buttons are made in the UK by Courtney & Co.

- Courtney & Co. are the last traditional button makers in the UK.

- The buttons used on our garments are made for Corozo and Codelite®.

- Our buttons are dyed using eco friendly, Oeko-tex standard 100 dyes in custom colours.

- All of the buttons we use are sustainably sourced, utilising natural and biodegradable materials.

Discover our cardigan collection which all use Courtney & Co. buttons.

Recent Posts

GS Collections

GS Sock Subscription

Subscribe and each month you'll receive a surprise pair of socks showcasing Genevieve's signature blend of premium yarns and contemporary patterns in seasonal, statement colours.